EC egg marketing standards regulations (EMR1)

Date published: 16 March, 2016

Guidance for anyone planning to register as an egg packing centre business.

Table of Contents

- 1. Introduction

- 2. Egg packing centres

- 3. Characteristics of eggs

- 4. Marking of eggs and egg packages

- 5. Records

- 6. Packaging

- 7. Storage and transport conditions

- 8. Adminstration and enforcement

- 9. Enquiries

- Annex A - egg quality standards

- Annex B - labelling

- Diagrams

- Download this guidance

1. Introduction

You should read this guidance carefully before completing the 'Application for registration of a packing centre' form (EMR2).

This guidance is intended as a general guide to the requirements of European Community law on egg marketing which is applicable in all European Union Member States.

It isn't a complete and authoritative statement of the law. If you wish to know more about egg marketing legislation, you should refer to the regulations set out below.

1.1 Regulations

The Eggs and Chicks (Scotland) Amendment Regulations 2010

The Welfare of Farmed Animals (Scotland) Amendment Regulations 2002 (as amended)

The Registration of Establishments Keeping Laying Hens (Scotland) Regulations 2003 (as amended)

1.2 Purpose and objectives

These regulations lay down rules which apply throughout the European Community.

Minimum standards of quality and weight grading, marking, packaging, storage, transport and presentation for retail sale of eggs are set to ensure they are marketed on a fair and competitive basis. The rules make sure that the quality of eggs is maintained.

1.3 What the regulations cover

The regulations apply to hen eggs marketed within the Community. They do not apply to eggs sold direct by producers to the final consumer at the farm gate or locally door-to-door*.

However, to be exempt the eggs must be from the producer’s own hens.

*Producers with up to 50 laying hens may sell their eggs at a local public market, provided that the name and address of the producer is indicated at the point of sale. Producers with more than 50 hens must also stamp their eggs going for sale at a local public market with a producer code.

Producers with more than 350 laying hens must be registered regardless of how the eggs are marketed.

Minimum standards for housing hens in certain types of production such as free range and cage are also covered (see ‘Explanatory leaflet EMR14’).

1.3 What the regulations cover

The regulations apply to hen eggs marketed within the Community. They do not apply to eggs sold direct by producers to the final consumer at the farm gate or locally door-to-door *.

However, to be exempt the eggs must be from the producer’s own hens.

* Producers with up to 50 laying hens may sell their eggs at a local public market, provided that the name and address of the producer is indicated at the point of sale. Producers with more than 50 hens must also stamp their eggs going for sale at a local public market with a producer code.

Producers with more than 350 laying hens must be registered regardless of how the eggs are marketed.

Minimum standards for housing hens in certain types of production such as free range and cage are also covered (see ‘Explanatory leaflet EMR14’).

2. Egg packing centres

A premises used to grade eggs is termed a "Packing Centre".

There is no minimum throughput qualification for registration of a packing centre. If your business is covered by the regulations you are required to apply to register your premises by contacting The Scottish Government Poultry Unit.

Contact details are below at Appendix C. You may also be required to apply to be approved as a food business by your local authority before trading can commence.

2.1 Activities of egg packing centres

Eggs should be graded, marked, packed and labelled within 10 days of lay.

Containers of ungraded eggs received at a packing centre must bear the following labelling information:

- name, address and distinguishing number of the production site

- number or weight of eggs

- laying date or period

- date of dispatch

Packing centres must grade, mark and pack eggs within 10 days of the date of lay. If eggs are to be delivered to a second packing centre they must be Graded, Marked, Packed and Labelled Class A before leaving the first packing centre.

2.2 Requirements for approval

To qualify for registration, your premises must have:

- suitable candling equipment continuously staffed and allowing the quality of each egg to be examined separately

- a device for measuring the air cell

- a machine for grading the eggs by weight

- one or more approved balances for weighing eggs

- equipment for marking eggs with a producer code

Provided your equipment is of the required standard, authorisation will be granted for packing centres and a registered number will be allocated.

However, it should be noted that premises must be separately approved as food businesses by their local authority before trading can commence. We inform local authorities on receipt of packing centre applications.

2.2 Requirements for approval

To qualify for registration, your premises must have:

- suitable candling equipment continuously staffed and allowing the quality of each egg to be examined separately

- a device for measuring the air cell

- a machine for grading the eggs by weight

- one or more approved balances for weighing eggs

- equipment for marking eggs with a producer code

Provided your equipment is of the required standard, authorisation will be granted for packing centres and a registered number will be allocated.

However, it should be noted that premises must be separately approved as food businesses by their local authority before trading can commence. We inform local authorities on receipt of packing centre applications.

3. Characteristics of eggs

3.1 Grades of eggs

The regulations specify the minimum characteristics for Quality Grade A (see Appendix A).

All eggs which do not meet these requirements are Grade B and may only be passed to approved food industry undertakings. Grade A eggs may be described as “Extra” if they meet certain additional conditions.

Further advice on quality testing can be obtained from your egg marketing officer.

3.2 Grading of Class A eggs

Class A eggs shall be graded by weight as follows:

- very large (XL) 73g and above

- large (L) 63g up to (but not including) 73g

- medium (M) 53g up to (but not including) 63g

- small (S) below 53g

Other points to note:

1.eggs may also be marketed as ‘eggs of different sizes’ with a minimum netweight of eggs in grams

2.there must be a mixture of sizes in (weight gradings) in each pack

3.additional terms, which may not be misleading, can be used when sellingeggs under their specific weight grades i.e. it must also include the official weight grade terminology

4. Marking of eggs and egg packages

4.1 General provisions on marking (mandatory)

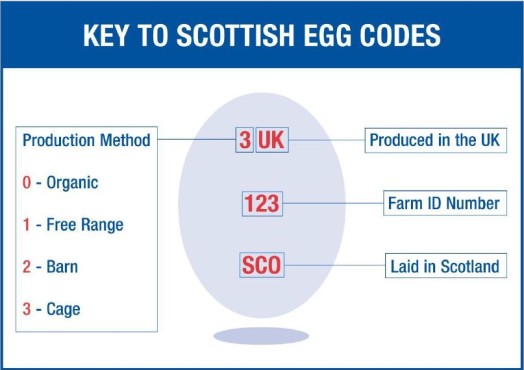

Individual "Grade A" eggs must be marked with the appropriate producer(s) code (issued by this department) which, in turn, should be explained on the pack or separate notice.

For example:

4.2 Indication of date of minimum durability (mandatory)

All large packs and small packs must bear an indication of minimum durability (the 'best before' date).

The maximum best-before date is 28 days from the date of lay but eggs must be delivered to the consumer within 21 days of lay.

The 'best before' date may be indicated by two sets of figures representing the day and the month e.g. BB 2303 or the day in figures with the month represented in by up to four letters e.g. BB 23MAR. Zeroes must be used to pad out single digits.

In the case of loose egg sales an indication of 'best before' date must be applied in such a manner as to be clearly visible and unequivocal to the consumer.

Eggs must be graded, marked, packed and labelled within 10 days of lay.

4.3 Consumer advice (mandatory)

An indication on packs in clearly visible and legible type advising the consumer to 'keep eggs chilled after purchase'.

4.4 Indication of poultry rearing methods (mandatory)

All large and small packs, or a sign in the case of loose eggs, must bear one of the following descriptors in such a manner as to be clearly and unambiguously visible to the consumer: 'Eggs from Caged hens', 'Free Range Eggs', or 'Barn Eggs'.

Explanatory guidance EMR14 explains the criteria for each of these descriptions. Producers who do not pack their own eggs should notify their Area Egg Marketing Officer before supplying a packing centre.

4.5 Indication of the packing date (optional)

An indication of packing date may be indicated optionally. This date must follow the same format as the Best Before date.

4.6 Recommended sell-by date (optional)

In addition to est Before date (and packing date), the recommended sell-by date may be marked on the eggs or packs during packing. The recommended sell-by date shall not exceed the maximum time limit of 21 days after lay. The date must follow the same format as the Best Before date.

4.7 Indication of how laying hens are fed (optional)

Additional optional indications of how laying hens are fed may be applied to eggs and packs. Reference may be made to cereals as a feed ingredient only where they account for at least 60 per cent in weight of the feed formula given of which no more than 15 per cent of cereal by-product may be part.

Without reference to the minimum of 60 per cent referred to above, where reference is made to a specific cereal, it shall account for at least 30 per cent of the feed formula used. If specific reference is made to more than one cereal, each shall account for at least five per cent of the feed formula.

4.8 Indication of ‘extra’ eggs (optional) or ‘extra fresh’

Until the ninth day after laying, eggs may be marketed as 'Extra' or 'Extra Fresh' as an additional quality indicator. Eggs can only be marketed in this way when eggs are sold in packs and:

- eggs are graded, marked and packed within four days of lay

- the air cell is no more than 4mm in height

- the laying date is shown on the packs

- the extra fresh until date is shown on the pack

5. Records

Detailed records should be maintained by packers, producers, collectors, and approved food industry undertakings. Additional records are also required where eggs are marketed with a description of how laying hens are fed.

5.1 Producers

Separate Records for each production type by site showing:

- the date of placing, age at placing and number of laying hens

- the date of culling and the number of hens culled

- daily egg production

- number or weight of eggs delivered per day

- number and weight of eggs sold from the farm-gate

- names and addresses of purchasers and the establishment number

In addition for eggs marketed under a feed description the following should be recorded:

- quantity and type of feed supplied and/or mixed on site

- date of delivery

- the name of the manufacturer or supplier

Records must be kept on farm for at least twelve months after the flock has been disposed of and are subject to unannounced inspection.

5.2 Packers

Separate records must be kept for each production description (e.g. free range) or feed description (e.g. produced by hens fed on cereals) detailing the following.

Records to be kept where applicable:

- the quantities of ungraded eggs they receive, broken down by producer, giving the name, address and producer code and the laying date or period

- after the eggs are graded, the quantities by quality and weight grade

- the quantities of graded eggs received coming from other packing centres, including the code of those packing centres and the date of minimum durability

- the quantities of ungraded eggs delivered to other packing centres, broken down by producer, including the code of those packing centres and the laying date or period

- the number and/or weight of eggs delivered, by quality and weight grade and by purchaser, with the name and address of the latter, including packing date in the case of Class B eggs or the date of minimum durability in the case of Class A eggs

- packing centres shall update their physical stock records each week

- records and files referred to above shall be kept for at least 12 months from the date of their creation;

- where Class A eggs and their packs bear an indication of how laying hens are fed, packing centres using such indications shall keep separate records in accordance with the above

Records must be kept by the packer for at least 12 months.

5.3 Egg collectors

Collectors, who by definition transport ungraded eggs from registered egg producers to registered egg packing centres, food industry or non-food industry, must be registered as a food business with their local authority.

Records to be kept:

- the quantity of eggs collected, broken down by producer, giving the name, address and producer code, and the laying date or period

- the quantity of eggs delivered to the relevant packing centres, broken down by producer, giving the name, address, packing centre code and the laying date or period

6. Packaging

Egg packs may be of any size.

Unsealed keyes trays are not regarded as packs but loose egg sales. Keyes trays cannot be regarded as packs unless contained in wrapping, such as shrink-wrap.

Eggs on Keyes trays should normally be packed in boxes which comply with the labelling requirements for packs or boxes. When eggs are marketed loose on keyes trays in palletainers or display units at retail, the containers must comply with the labelling requirements for a pack (Appendix B).

Packs should be shock-resistant, dry, clean and in good repair. They should be made of materials which protect the eggs from extraneous odour and the risk of quality deterioration e.g. fibre pulp, plastic or polystyrene.

Packs, boxes or keyes trays may be re-used provided they are clean and in good condition, and that they do not show old markings which may confuse or mislead the purchaser. Materials suitable for packs or boxes include shrink-wrapped packs of various types, fibreboard, hard bodied or plastic coated containers.

Labelling information for ungraded eggs from a producer to a packing centre (Appendix B – Ungraded eggs (ex-farm)) shall be applied* to the transport packaging and be contained in accompanying documents.

A copy of those documents shall be kept by any intervening operator to whom the eggs are delivered. The original documents shall be kept by the packing centre that grades the eggs.

*Applied means attached in such a way that the information cannot be removed prior to grading. A slip of paper under an egg or a keyes tray on top of a pallet is not acceptable. A label secured under shrink wrap or stuck to a consignment would be acceptable.

7. Storage and transport conditions

During storage at the producers premises and during transport eggs must be kept in clean, dry places, free form extraneous odours and effectively protected from shocks and from the effects of light and excessive fluctuations in temperature. Class A eggs must not be stored artificially at temperatures below +5°C.

8. Adminstration and enforcement

These regulations are enforced in Scotland at marketing stages other than retail by The Scottish Government Poultry Unit. At retail level, enforcement is carried out by the Local Authority. Producers, collectors, packing centres and wholesale outlets are visited periodically to ensure that the Regulations are being complied with.

9. Enquiries

If you have any questions on any aspect of the egg marketing regulations, please contact the egg marketing officer for your area.

Annex A - egg quality standards

(EMR1) Annex A – egg quality standards (Grade A)

Cuticle:

- normal shape

- clean

- undamaged

Shell:

- normal shape

- clean

- undamaged

Air-space:

- height <= 6mm or <= 4mm for eggs marketed as ‘extra’(Section 4.10)

- stationary

Yolk:

- visible on candling as a shadow only

- without clearly discernible outline

- slightly mobile upon turning

- and returning to a central position

White:

- clear

- translucent

Germ cell:

- imperceptible development

Foreign smell:

- not permissible

Foreign matter:

- not permissible

Cleaning / washing:

- not permitted

Egg quality standards (Grade B)

Grade B eggs are those that do not meet the quality criteria set out above for Grade A.

Grade B eggs should not be sold for human consumption, but can be passed to the food industry for processing.

Annex B - labelling

Ungraded eggs (ex-farm):

- producer name

- producer address

- producer code

- laying date or period

- date of dispatch

- number of eggs

Class A eggs must be labelled with at least the following information:

- eggs (fresh eggs)

- name and address of the packer or the company packed for

- packing centre code (uk7xxx)

- quality

- size

- number of eggs

- best before date

- method of production

- consumer advice to keep chilled

- explanation of egg code (may be on inner or outer surface of pack)

Class B eggs or Downgraded Class A eggs (for Food Industry) must have the following:

- Class B or ‘B’

- packing date

- packing centre code

Industrial eggs (for non-food Industry) must be under cover of a red band or label and display the following information:

- INDUSTRIAL EGGS (in letters at least two centimetres high)

- the words “unsuitable for human consumption” (in letters at least eight millimetres high)

- name and address of dispatching operator

- name and address of the destination operator

- category of animal by-product (1, 2 or 3)

Diagrams

Diagrams offering an illustration of the organisational structures involved in egg marketing.

Download this guidance

Click 'Download this page' to create a printable version of this guidance you can save or print out.