Supporting guidance for Ditch Blocking – Plastic Piling Dams

This is an old version of the page

Date published: 30 March, 2015

Date superseded: 20 January, 2022

Choice of dam – plastic piling or peat dams?

Plastic piling is light, versatile and slots together on site. If properly installed, plastic piling dams can form a good watertight seal that will last for decades. Plastic piling dams are useful in the following situations:

- where only a small number of dams are required and it is not cost effective to get an excavator on site to make peat dams

- on steeper gradients or for wider ditches where the weight of water could cause peat dams or unreinforced piling dams to fail

Locating dams

Ditches are not always apparent on the ground and in some cases Sphagnum may grow across the top of a narrow ditch whilst water actively flows in the base. Before going on site, we recommend you check aerial photographs for linear changes in vegetation because they may indicate hidden ditches. The intensity of damming required will depend on the flow of water in the ditch, the degree of slope and the amount of water held back by individual dams.

Generally dams are placed at 20 to 30 metre intervals. It is expected that the final water level from the lower dam will rise half way up the upstream dam. The final water level should be at the peat surface or no more than 20 centimetres below the surface.

Select a location for your dam where the ditch narrows to form a pinch point. This provides a firmer footing for the dam and uses less material. Where ditches are running parallel, stagger the dam positions, to increase the wetting effect on the surrounding peat. The wetting influence of each dam will extend sideways into the peat for up to 10 metres.

As a guide only one third of the dam will be visible on completion. The total quantity of plastic piling required will be approximately three times the cross-section area of the ditch. Plastic piling can be used in two configurations, box section and z-ribbed depending on the width of dam required.

Dam construction – small dams

Piling will only create a good seal if driven into at least 75 centimetres of solid peat. Solid peat is usually found below the 50 centimetres of soft peat in the base of the ditch.

Position the longest pile in the deepest part of the drain. Use a sharp spade to pre-cut the outline of each pile in the surface vegetation. Push the pile into the peat using your own weight. Ensure that the piles remain vertical as it will become increasingly difficult to insert piles if they lean in any direction. Using a mel, drive further and when firm guide adjacent piles into their cams, repeating the process. Continue until all piles are firm in the peat.

Shape the dam to form a gently curving upstream 'C' shape at the ends. This shape gives the dam strength and increases the amount of water retained. The dam must extend well into the banks of the ditch. As a rule of thumb the width of each one of these extensions into the bank should equal the width of the ditch.

Continue driving the piles starting at the centre, until all piles are approximately 30 centimetres above bank level. Leave the dam to fill with water, as the last firming is best done with water behind the dam to lubricate the piles. Finally, hammer the piles until they sit no more than 10 centimetres above the ground surface. The dams should not be visible above the vegetation. But do not hammer the piles below the ground level, as this reduces the amount of water held and spread across the adjacent peatland.

You will need to check how well the dams are working and make adjustments if necessary.

Where there is a strong flow that would cause erosion around the sides of the dam, create an overflow by driving in the two piles in the centre of the dam to about 5 to 10 centimetres lower than the adjacent piles.

If there is a strong flow of water around the sides of the dam, add extra piling where the water is flowing round until the water level reaches the overflow.

If there is likely to be a lot of water coming over the overflow, place branches, heather sods or tree trunks in the flow to stop undercutting of the dam. This is particularly important for the lowest dam in the ditch, as there is no water below the dam.

Dam construction – large and reinforced dams

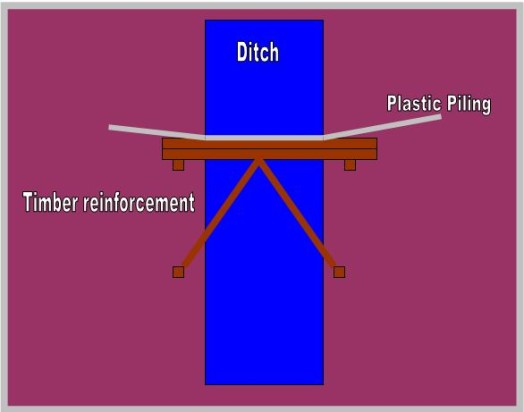

On ditches wider than 1.5 metres, plastic piling and peat dams without reinforcement or support will bow, slump and heave, due to the weight of water. In addition, at the end of a long run of dams particularly peat dams (i.e. 20 dams or more) we recommend you reinforce the last two dams to act as insurance should any dams fail.

Reinforcement takes the form of timber or metal piles but in general, timber reinforcement is adequate. It usually entails the use of timber immediately behind the dam with diagonal timbers linked to the ditch bank. Reinforcement is also used on the last two or more dams on the lower end of a large run of dams.

Timber supports are placed immediately behind the dam and fixed to the ground by stobs at either end. The purpose of the support is to reduce bowing of the dam structure.

Generally the timber used for reinforcement is treated. If the timber has been treated recently it should be left to dry properly, to ensure the preservative is completely fixed to the timber and surface residue is taken up. Oak, elm and European larch can be used as untreated timbers.

In most cases it is sufficient just to use two 4x4 posts bolted together, supported by two 4"x 4" stobs at either end. By bolting the two pieces of timber together with grain in opposing directions the combined structure will be much stronger than a single piece of wood of similar dimensions. The last two dams at the end of the run should have the diagonal supports which are held in place by stobs. The maximum length of 4"x 4" timber is usually is 3.6 metres. If wider dams are proposed, stagger the length to ensure the timber joints are not opposite each other and so weakening the structure.

A-frame dam with diagonal timbers linked to the ditch bank – Credit: Andrew McBride, Scottish Natural Heritage

Diagram showing timber reinforcement – Credit: Andrew McBride, Scottish Natural Heritage

Producing a plan

Include a Ditch Blocking Plan your application. You should state in your plan which methods you are using and you should state why these have been selected. Include details of the number and locations of the ditches and dams.

If you are producing another management plan, for example a Moorland Management Plan, it may be appropriate to include details of your ditch blocking work as a sub-section of this plan.

Related management options

Related capital items

Further information

There is more detailed guidance on the siting, installation and maintenance of plastic piling dams available from the Peatland Action page of the Scottish Natural Heritage website: